sTanley steam car packing wrenches11/27/2022 JOE SHUKAY Packing nut wrenches originally made by Ole B. Vikre. Jr. We had one set and we copied and made a set for each car, 4 wrenches in each set

0 Comments

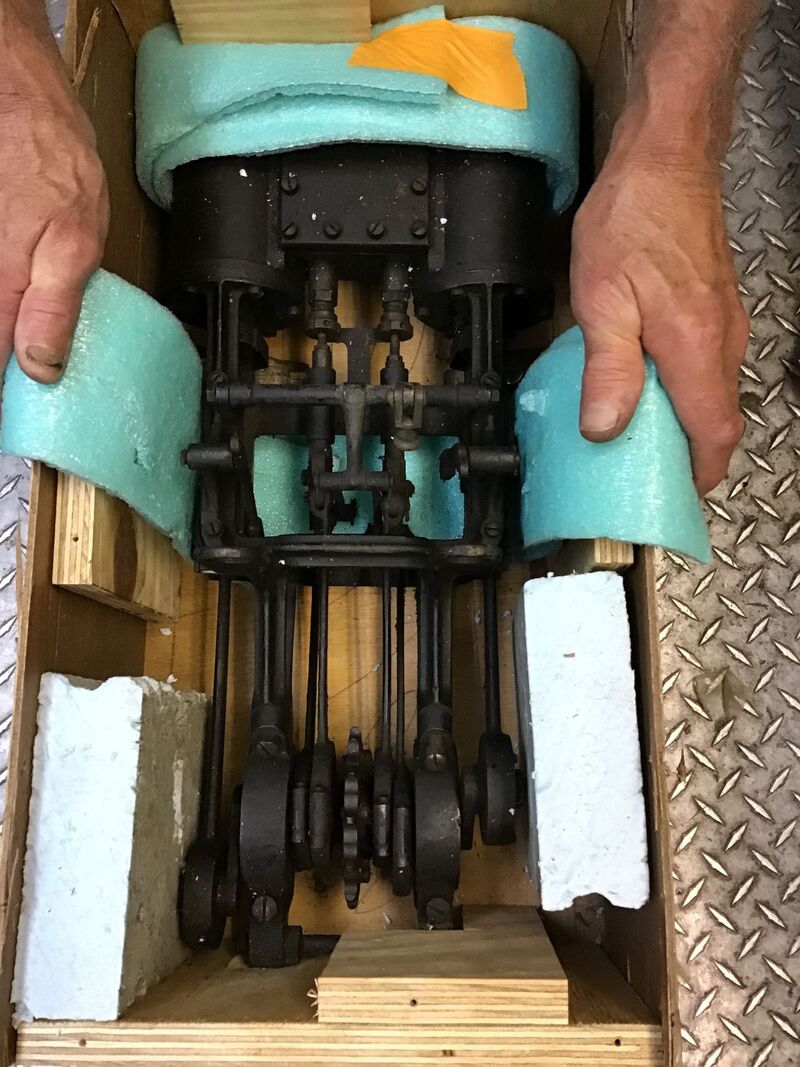

early stanley engine rebuilds11/24/2022 Joe Shukay · Early Stanley, small frame 30HP engine we rebuilt years ago as a spare engine for the Model 85. I helped rebuild about 10 Stanley 20-30hp engines since i started working on them. I really enjoyed that. veteran car rims11/16/2022 Chris Wedgwood shared a profile.

Group expert · 26m · My brother Matt and I have purchased this company from New Zealand and are really excited about getting up and running soon https://www.facebook.com/profile.php?id=100087755296105 Chris WedgwoodFriends who like Steam Car Network · New burner and pilot light for 1904 White steam car completed and tested today. Manufactured by Chris Wedgwood. NEW RODS FOR STANLEY STEAM CAR10/9/2022 Andrew JohnsonNew crossheads and connecting rods coming along for the model 61. A lot of changes and re thinking things from my original plans but that is what a steep learning curve is all about. Waiting on a reamer to come for the conrod bolts to make the rods whole. The engine should be running in at the lake goldsmith steam rally in two weeks.

help identifying steam car engine7/27/2022 Bill Etter

[email protected] Post Title Help Identifying engine This engine has been floating around my family for many years. If memory serves me it has always been described as a Stanley Steamer engine. Would like to know if anyone can give any specifics. Many years ago (50 or 60) when I was younger my dad ran it with compressed air. It's time for it to move on. Thanks for any assistance.. Joe Fedullo has now produced a batch of new style Jets for Stanley type vapourising burners, which he describes below: I have been playing with Jet designs and think I came up with something that might be better than what is currently available commercially. Take a look and let me know what you think. Changes to the exit tip: On the outside, the simple 3/8" hex is replaced with a smaller 5/16" hex that has a smooth taper down to the nozzle exit. The idea of the transition is to smooth flow of the entrained. Herb de la Porte has observed eddy currents around standard jets at the nozzle and this seems like a way to help rectify that. He also has a set of old jets he found somewhere that have a similar design. He lent me one I used to copy the head. On the inside, I added a 5 degree taper at the exit of the inner hole to create a diverging nozzle. Since the flow is sonic and therefore choked, the diverging nozzle should allow further acceleration of the fuel flow and hopefully more air entrainment. I used about a 2:1 area ratio for the diverging nozzle assuming a #56 jet. With smaller jets, it will be a expanded a little more. I then added a 1/8" radius right at the exit after the taper to help the "pricker" find the hole, but hopefully these don't need to be pricked very often due to the changes in the backside of the jet Backside: Even though I use the multi port jets from Vintage Steam, I have noticed when the rearward centre hole clogs, the flow goes way down even though there are 12 other holes for it to go through. A simple prick usually opens things right back up and I have never seen the radial holes clog when I remove the jets. I took some measurements and the diameter of the holy section of the current multiport jets is 0.196" and the drill for a 1/4-28 hole is 0.213 so there is only 0.0085" radial clearance for fuel flow. That gives about 0.0055 sq inch of area which is almost 4 times my # 57 jet area, (# 57 = 0.0015 sq inch) but empirically it doesn't flow when the back hole gets plugged. Maybe there is a boundary layer issue with such small clearances, or maybe carbon dust plugs up the circumference. To help, I made several changes to the backside of the jet. First I reduced the minor diameter to 0.175". This should allow much more flow to get to the radial holes perpendicular to the main flow axis. The other big change was the addition of 6 holes on the tapered surface around the main rear hole. These holes are perpendicular to the chamfer pass through the axial hole and also open to the cylindrical surface. I would think these holes eliminate the need for the radial holes, but I started thinking they all converge at a single point which was a potential area for a blockage so I added a dozen radial holes as well. The back of this jet is now Swiss cheese... It looks like a pretty tricky part to make, but my first preliminary quote came back at $10.06 each in a quantity of 100. Before I get deeper into the quoting process, I wanted to get feedback / see if you guys have any design change ideas. Also if anyone is interested in splitting up the order I can keep you posted as I work through the quote process. I've made a couple of changes based on some great feedback, which I really appreciate. I will wait a couple more days for further feedback then send them out for production: 1) I've increased the length of the bullet shaped outer tip per feedback from Howard. 2) Changed the spacing of the holes perpendicular to the chamber at the fuel inlet, such that they all do not intersect at the same point giving a potential clog point. They are now in 2 arrays of 3 giving 2 intersection points. 3) All holes are now #66 which was the smallest size anyone I know uses. They can easily be drilled out to any larger size needed. SEE FULL ARTICLE IN THE MAGAZINE ON THIS WEBSITE

Shame on the Steam car club of Great BritainDear Basil, The committee of the steam Car Club of Great Britain all agree that your presence at any of its events as an entrant or guest would not be well received by a majority of its members. At this moment in time we are not willing to compromise on this decision and it is not open for debate. Regards Harold Bell – chairman of the Steam Car Club of Great Britain. The committee of the club continues to carry a 10 year vendetta against Basil Craske. Hiding behind the members.

Most if not all members are disgusted by the committee members who behave in such a way, not all committee members truly agree. Steam MotorBike Help Wanted1/14/2022 Hello there,

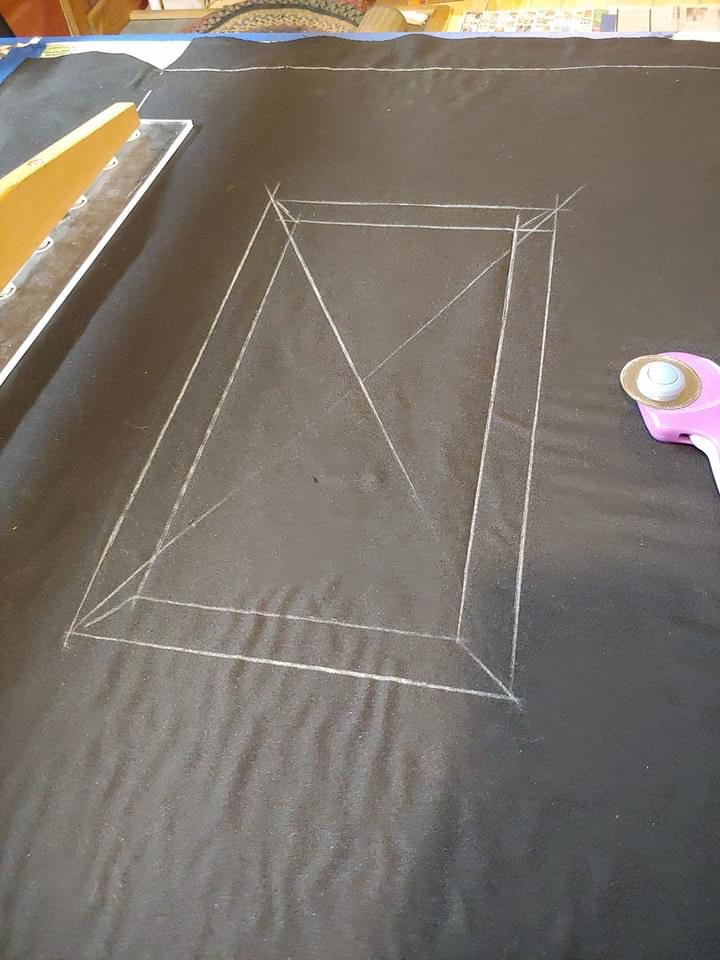

Through a bit of research I have brought myself to you, I am looking at making my motorcycle (see photo) steam powered and would like to have a chat to someone in the know as to whether it is possible or not, I am looking at the v twin steam engine but I am unsure on boiler size or water tank size that would be needed, Can you assist or maybe be involved in the project? Regards Scott Sarah moon makes steam car hood1/9/2022 This weekend's progress. Because it's my first attempt, I didn't get everflex/bison vinyl and opted for a UV treated vinyl on sale instead. It is much softer and super stretchy in comparison. And I recommend just getting the good stuff cause I have to compensate on a few things. I used a multipurpose adhesive spray to attach the lining material- I can now forget about securing the layers for the rest of the project. On the parts that were used as bracing or interfacing, I will be adding a layer of a heavy interfacing to combat the vinyl stretch. The back's 3 panels are complete minus hardware.

Simon Webb getting ready for the London to Brighton 2021Remembering Brent Campbell (1945-2021)10/27/2021 We regret to report that Brent Campbell, one of the most prominent members of the Steam Car Community, passed away on the 24th October, after a long illness. Brent had been around Stanleys since the early 1950's, when he rode in his grandfather George Monreau's (who had worked for the Stanley Factory) 1913 Model 65. A keen driver, Brent believed in using his car's rather than just displaying them; his first Stanley clocked more than 35,000 miles in the 13 years of his ownership. Indeed, in his Stanley model 85 he clocked 424 miles in one day, and regularly took part in the Trans Continental and Red Rock Tours. He was an absolute authority on Stanleys, and was a great help to many Stanley Owners, always offering help, as well as historical information. Indeed, his contribution to the Stanley Steamer Book, written by Kit Foster,and produced by the Stanley Museum, was invaluable. Brent was not a person who believed in the brake pedal. In 2006, the Buick Hot Rod he owned crashed when a rear tyre blew, throwing the car firstly into the central reservation, then back across the highway to the nearside followed by five somersaults, destroying the car. Brent suffered multiple injuries in addition to three vertebrae in his spine needing to be frozen together. After a long rehabilitation period, Brent was back driving his Stanleys. Brent had a great collection of steamers over the years, including a Stanley CX (sadly lost at the bottom of the Atlantic after taking part in the centenary of the London to Brighton Veteran Car Run, when the container ship broke in two), a Stanley Model K, a Stanley Model 74, a Stanley 731, Stanley 82 and Stanley 85. But perhaps the cars he is known best for are the two Raymond Stanley Specials he owned, Effie, a 1911 30HP Roadster, and a 1912 30HP Roadster, the latter a painstaking multi year recreation by Brent. With Brent, alot of Stanley and Steam Car information passes. He will be sadly missed. Images in slideshow above courtesy of Wumf Tuxworth. Drilling a stanley steam car boiler9/15/2021

Stanley Boiler Being Tapped7/14/2021 Bill Barnes writes: Drilling and Tapping a Stanley Boiler. By code you shouldn't drill into the weld .. As shown in pictures I try to stay away from the tubes as much as possible.. You run the pipe tap in a little over half way on the tap and check it to your fittings . I never use bronze or copper fittings in the boiler.. Steel on steel is the best .. Pipe tap chart below . Steam Steam Stanley Rear Brakes Updated7/14/2021 Burt Hermey writes: Yesterday the Stanley's engine/rear axle assembly came home from the brake shop. It's now sporting two new disc brakes in place of the old band brakes. Today begins the process of reinstalling it. Lots of little things to remember along the way! Once in the car the engine will get a bath of Gunk, then the crankcase cover will be installed (with new gasket, of course!) 2021 Midwest Steam Car Tour7/14/2021 Steam Car Enthusiasts,

I wanted to reach out and announce the 2021 Midwest Steam Car Tour. We are shifting the tour days slightly from past tours. We will be touring starting on Saturday September 11th and the final tour day is Thursday September 16th 2021. The tour is based out of Cedar Rapids, IA and the host hotel is The Hotel at Kirkwood. You can book your stay at the hotel by calling 319-848-8700 or toll free at 877-751-5111 and ask for the Midwest Steam Car Tour block. The hotel only has a little over 70 rooms but has a very large parking lot for trailers. We hope you will join us for a nice roads tour. More details to follow. We are excited to see everyone out touring again. If you have any questions, please feel free to contact me by email or phone below. Thank you, Mark Culver 319-981-2799 [email protected] 2021 Eastern Steam Car Tour6/30/2021 The 2021 Eastern Steam Car tour is underway, with the first two days having taken place. Photos courtesy of Billings Cooke, Sarah Moon, Herb de la Porte, Steve Bragg, and Mark Turner. Stanley Brake Overhaul6/30/2021 Burt Hermey writes: The engine and rear axle are out of the Stanley, and will be heading to the brake shop tomorrow. Here it's hanging on the garage hoist. london to brighton 20216/30/2021 |

For instructions on how to add to our community's blog post, please visit our Get Involved page by clicking on the link above!

Archives

November 2022

Categories

All

|

||||||

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed