|

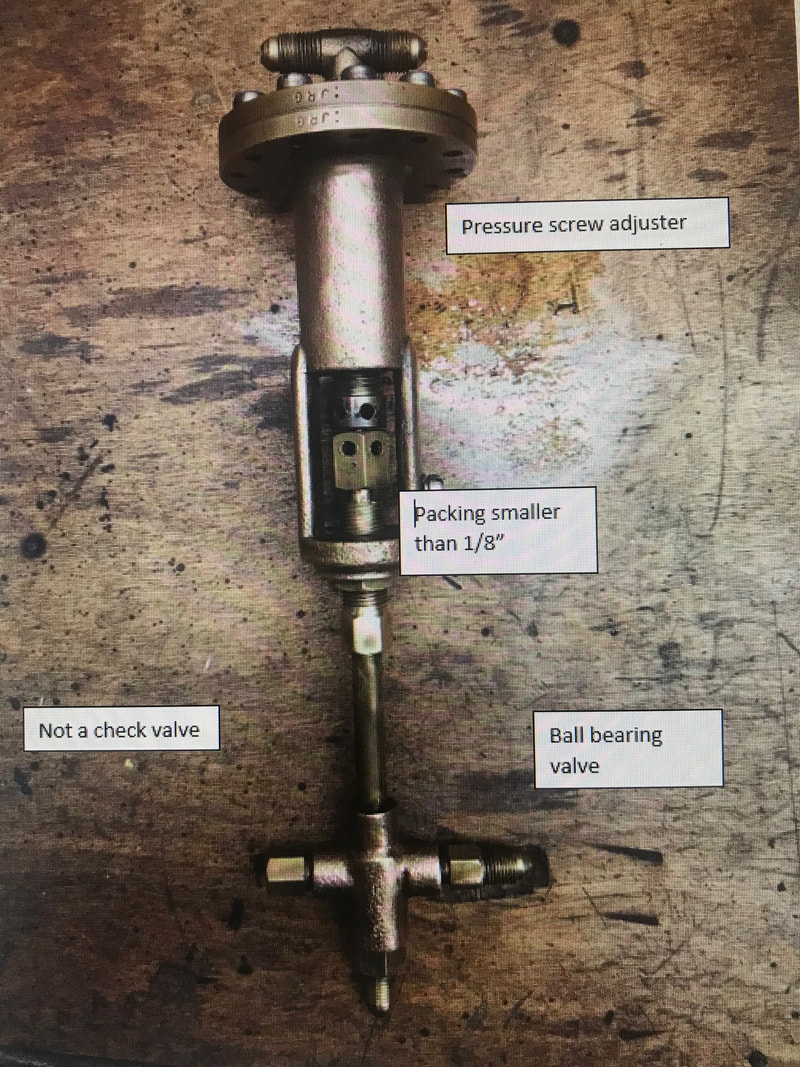

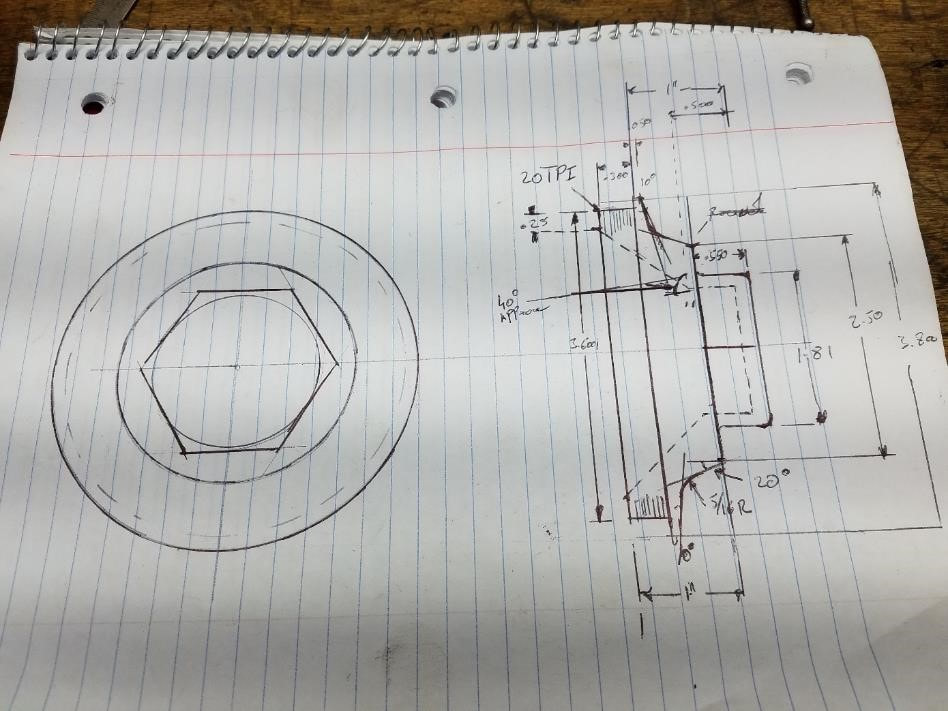

Fuel Filters I installed 2 fuel filters/water separators in 2017 after noticing how much filth got into the system. I feel the pumps, Fuel automatic, Check valve and steam automatic will be well served with clean fuel. In addition to that, the 55gallon drum holding the Jet-A seemed to not get rid of water after rain, so I had some worries there. Parker industries introduced the RACOR SNAPP 2 micron water diesel fuel separator. It is a one piece unit of which the insert is easily replaced. Water settles in a transparent bowl and is easily drained. The valve is the main shutoff at the fuel tank. Fuel was unable to pass through anymore. For the Hexane system, I installed a RACOR 110A 10 micron fuel filter. It can be pressurized and it was plumbed in with copper tubing. It should perform to 35 psi Update 8-17: the main fuel system has performed extremely well. For some reason, I have been draining a lot of water from the main fuel system and the filter will likely need replaced already. I don’t think it was as crucial for the pilot fuel JRG means it originally came from Goulds. When assembling the bottom part, the system will bottom out when about three threads are showing. The assembly will be less than half a turn past where it needs to be. There is not a lot off travel and there is a lot of tension on the spring Exhaust System.. The initial system had big gaps from where the engine pushed it out before the engine steam intake was shortened. Welded the system closed to where the steam discharge pipe came in. I’m puzzled with the pipe. It is simply soldered together and seems to hold fine Tailpipe. I had soldered the tailpipe in the past/ it did not hold so I ended up welding it (TIG with High Silicon Brass rod from mcmaster) Pilot Light. Bottom unit was a Propane setup. I converted it back to Hexane. Pilot body by Don Bourdon Built a new needle from 1/8 steel rod using lathe grinder. Threaded it to standard #6 and threaded the casting accordingly. It needs to stick out past the seat as it guides gasses into the casting. It is easily bent on removal Sight glass (Gauge glass). An extremely useful study source is the klinger product catalogue at http://www.klinger.kfc.at/index.php/en/component/jdownloads/send/3-product-catalogues/19-product-catalogue-gauge-glasses The unit on the steamer is as size 1B reflex gauge and can be found at mc master at https://www.mcmaster.com/#gauge-glass/=1cljafz The following came from Pat Ferrell in Washington state after a facebook inquiry: I do use the McMaster reflex gauge gaskets, as they are a good value and they fit well. I use an antisieze on my gauge's bolt threads and I torque them starting from the center bolts like torquing a car's head gasket. Tighten a little at a time. I torque them when the gauge is cold, and then I re-torque them after the gauge has been fired and has cooled down again. I re-torque them every spring as an annual service. How many pounds? I torque them firmly, as I don't use a torque wrench, I don't want to guess the torque. In the 33 years of steaming, I have never had the quality of a reflex gauge glass degrade from use. Through the years I have lost about 3 gauge glass gaskets while on the road. I always carry spares with me. Burner (Baker Style. Made by Blazik) Remove and install: the burner will not come out with the car at its normal level. Lift the body and install two pieces of 2x4 to keep it up. A long enough piece of plywood held up in two spots will help finesse the thing out of the car but is indispensable to tweak it back in Disconnect the steering bar to give more room Burner make-up. The burner sits in an insulated pan. The easiest way to take the burner assembly out of the pan and put it back in is by doing it upside down. The gas diffuser is simple but the pipes are above the pan. If the pilot goes out and raw kerosene is blown in, there is no way for it to leave other than by burning it off. I used muffler repair dope to seal the halves together and furnace cement to seal up everything else Use masking tape to cover the slits and protect them from cement. Use insulation between pilot and burner “Imperial hi-temp stove and furnace cement, Grey” seems easy to work with Everything is screwed together with #10 button heads Hubcap. lost a hubcap in Iowa, decided to make a new one from ultra machinable brass from mc master

0 Comments

Leave a Reply. |

Archives

December 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed