|

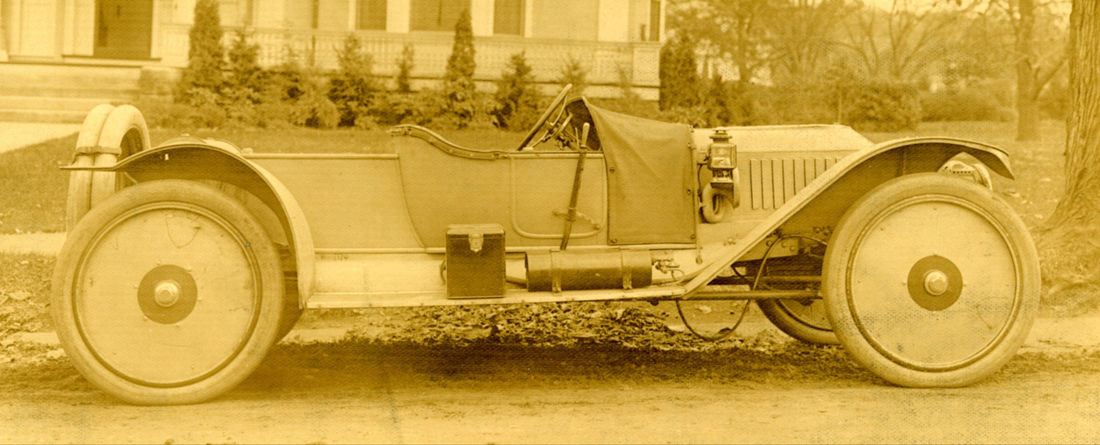

Part One of Brent Campbell's Steam Car Renovation. The car I am replicating is the second of three cars made especially for F.E Stanley's son, Raymond (1894-1985). As many many people know I restored the first car Raymond designed,which his father had requested the factory to build to what Raymond specified. Since Raymond was only 16 when the first special car for him was built (1910-11) FE surely had to over-see the "build" of the car at the factory.That is why i nicknamed it "Effie". Luckily this car is one of the survivors and its history has been verified and detailed information can be found on Kelly Williams "The Stanley Register Online"in the 1911 model year , serial number 6052. the second car built for Raymond was completed in April of 1912 and was serial number 6700 as verified by the original Stanley serial number book that is in the custody of Virginia Landry, Fred Marriott's (the test and racing driver for the Stanley Factory) grand daughter.This fits since the first car is recorded in the book as being delivered (sold) April,1912. The book has Fred`s name inscribed on the cover as it was his job to record the model,serial number,and delivery date when vehicles were sold. This car was not sold since it was still in use by Raymond in 1914 when the steering broke the second time. FE decided to dismantle the car after the second steering breakage which happened while Raymond and two of his Harvard classmates were on there way from Harvard to Raeburn Country Club in Brookline, Massachusetts on Friday afternoon for a game of golf. Each week the boys would try to best the previous week's time as Raymond told several steam enthusiasts during one of several interviews in the early 1980`s before his death in 1984. Ray said they were on track for a record time when the steering broke (again) and the steering wheel just went round and round in his hands with no connection to the front wheels. Luckily, he and his two passengers survived the crash and Ray walked away to the nearest house to call his father. It was after this last incident that F.E decided to dismantle the car. I used the word dismantle since those who have studied the Stanley twins know that "Maine Yankees" didn't throw anything away that could be used. I have no doubt that any usable parts were recycled at the factory! The serial number, date of delivery,and model were usually typed into the serial number book. Virginia Landry recognizes Fred`s hand writing and wrote in RWS 30HP 3P next to the number 6700.The 3P meant it was built to accommodate three people. . Fred Marriott didn`t like Raymond (pictured above) according to all accounts of people who new them both. Imagine an 18 year old owner's son bringing in his special car for service and advising the service manager of what needed attention. Fred would have to take care of his boss' son ahead of other scheduled work in all likelihood, even if the problem was minor such as a yellow pilot! No wonder Fred remembered the serial number, and description of the car since he probably had to drop everything to tend to it during the three years it was in service. Never "sold" but not forgotten by Fred! Ray liked his cars low with a racy look. He did graduate from Harvard with a degree in Automotive Design. The first series V nose Stanley condensing cars were designed by him and are generally considered the most attractive of the condensing body styles. "EFFIE" was almost four inches lower than production Stanleys at the time he designed it. Thirty horse power cars are large imposing vehicles, be it a model 87 touring car or a mountain wagon. The first car built for Ray is anything but large or impressive. Rather "a wolf in sheep`s clothing" in appearance. EFFIE IS PICTURED BELOW. The second car Ray designed was lower by almost eight inches. He could have been inspired by Mercer Raceabouts or American Underslungs which were very low compared to most other automobiles of the period. The wheels sported aftermarket period accessory disc plates screwed to the conventional wood spoke wheels on both sides which gave them a different look. He didn't like standard windshields but preferred a canvas covering which was commonly referred to as "Cambridge Windshield" the six different pictures from Ray's personal scrap book show that this windscreen was modified three times during the time he had this car. He told the interviewers that this was his favorite of the three cars built expressly for him. The pictures from Ray's scrapbook were vital in the ongoing effort to recreate this car accurately. Computer aid helped determine dimensions and generating design specifications. My son-in-law, Mark Herman, is the person who has brought the car to life along with one of his employees , Peter Kruger. Mark is a cabinet maker, Stanley owner, and has built or repaired over 25 Stanley and other steam car bodies up to now.This project (Ray`s car is my nickname for it but one Stanley friend has dubbed it "Ugly Betty" which reflects what many folks feel about the looks of this car!) has been far and away the most difficult build of any car done by Mark in the past. There are no internal pictures or information about how the factory made the numerous alterations necessary to lower the car. There are countless interference issues that have had to be dealt with. We try to imagine how Stanley might have solved the problem while considering solutions. (Knowing Stanley's, we think they opted in favor of the quickest ,easiest, cheapest way possible.) One is the steering, which they didn't get right since we know it failed three times. I have experienced five steering failures in three different Stanley`s over the years and figure my luck of being unscathed so far is going to run out one of these days. We now have a rolling chassis and plumbing has started as you can see from the pictures. This is one of the things I can do myself and enjoy the task. The three passenger body skeleton has been built by Mark and Peter and is now in Northport, Michigan being aluminium skinned by an expert craftsman thanks to Mike May who resides only five miles away and is overseeing the construction for me (not to mention hauling it as well!!) The car has a 55 gallon water tank,20 gallon main fuel tank, and the wheelbase is 130 inches. It is geared 55/60 or 1.09 to one. Curb weight is estimated to come in about 4000 pounds when finished. It is not going to be a performance car such as "Effie"which curbs at 3450 pounds, or a model K which weighs in at 2900 pounds, or an H5 which tips the scales at 2460 pounds. Hopefully it will be a comfortable, good cruising, decent handling steamer with a very low center of gravity compared to production Stanleys. Like an H5 or "Effie" it will have good weight distribution since there will be more weight on the rear than the front. (Most Stanleys understeer since much of the weight is in the front). I plan to run it as a chassis without fenders, hood, lamps,etc until it is all "dialed in"; besides it is more fun and faster while lighter than it will be in full dress!

1 Comment

UPDATE ON RAY STANLEY THREE PASSENGER 30HP ROADSTER Restoration by Brent Campbell Basil and Vicki visited with Martha and me last month while they were at their vacation home in Orlando, Florida. They came over for a visit and got to see the progress since their visit last year. You will remember that this is a recreation of the second vehicle of three Stanley’s that was built expressly for FE’s only son, Raymond. Ray designed each one (he graduated from Harvard with a degree in automobile design.) You will recall that this car was dismantled after two steering failures so we know it did not survive. Computer enhancement of the six pictures of it that came from Ray’s photo scrap book enabled my son-in-law to accurately replicate this car. I was blessed with many of the correct key components from Stanley parts gathered over the past forty years. The correct 30hp engine, front and rear axles, all pumps, valves, gages, automatics, original fittings, lamps, etc. gave me what Carl Amsley would have termed “A license to build”. Other hard to find items such as an original engine case, oil tank, correct roadster pedals, and all the leaf springs necessary to make a set were also procured or bartered for in some cases. Absolutely every part has been rebuilt before installation. Since my last report a new aluminum body was constructed around the wooden skeleton that Mark and his employee, Peter Kruger had formed. Much of the paint work has now been done. Don Bourdon recently painted the body and Loren Burch is doing the upholstery as this is being written. I completed the plumbing and all the necessary components were installed with the goal of having a running chassis. It often takes me a considerable amount of time to get a “new” car dialed in to run up to snuff. Making myriads of adjustments is much easier without dealing with painted body, fenders, hood, etc. It is also much easier to make improvement when these items are not in the way and there is no worry about scratched paint. The chassis was ready for a test drive in August. Over 500 miles have been accumulated with the aid of a compact GPS device about the size of a pack of cigarettes. Every test drive yields advancement and I am getting closer to a Stanley that performs properly. This vehicle has a 130 inch wheelbase [same as most condensers] and I am impressed with the ease of steering, excellent ride, and very good handling characteristics. Most Stanley’s under steer when cornering with few exceptions [a model H is a notable exception]. This car has a 55 gallon water tank located behind the passenger compartment, a 20 gallon fuel tank, pilot tank, and the engine hanger strap just below your rear end. All this weight in the rear makes for ideal weight distribution. In order to get the car as low as Raymond desired [it is almost 9 inches lower than a production car] the boiler and burner were located behind the front axle to eliminate bottoming out due to normal suspension travel The steering tie rod is modified so as to be under the perch poles instead of above them. The springs were moved to the outside and at the top of the frame rails instead of underneath. These are just a few of the changes that were made to achieve the desired height. While we were blessed with various external pictures there were none of the “innards” that showed how the numerous modifications were made to achieve the original design. This has made construction much more difficult than copying a regular production car where proper measurements, attention to authenticity of components, and assembly can result in a proper reproduction. Few assembled cars I have studied come close to being a correct, authentic reproduction. Most folks don’t take the time to research or bother to reproduce parts exactly so as to achieve an accurate finished product. {Basil Craske is one of the few exceptions. He takes the time to research, study original survivors, make and procure correct pieces, and pays close attention to accurate fit and finish to achieve an accurate result. Deviations are limited to improve practical drivability, and safety issues such as modern brakes and lighting. These are areas where owners that use their cars regularly consider these modifications absolutely necessary.} At the moment a feed water heater fabricated by Don Bourdon is being installed in the exhaust duct which should improve performance considerably. This is a much heavier car than “Effie” [the first car expressly made for Ray Stanley which did survive and I feel blessed to be its current custodian]. I don’t expect it will have the same level of performance since it will be about 650 pounds heavier when finished. My plan is to continue having fun with it in chassis form until fall before the body is installed. It will come back down to Florida again next November and the lamps, electrification, and speedometer installation will be projects for next winter. It should be completed by next spring. In the mean time I will attend at least three tours and put as many miles on the chassis as I can. Driving it in chassis form is a blast and performance is more exciting than when it is in full dress at maximum curb weight. Most people who see the original pictures from Ray Stanley’s photo scrap book don’t like it’s peculiar look due to the after market wheel discs and the unusual canvas windscreen. I hope it will be more appealing in the “flesh” since it is so low and very long. These attributes are not readily apparent in the original pictures. Ray Stanley did say that this was his favorite of the cars made for him when interviewed in 1980, four years before his death. Now that it is running I can well understand why this was the car he liked the most! PART THREE TO FOLLOW SOON

The final part of the story The six year project of replicating the second car designed by F.E.'s son Raymond W. Stanley and built by the factory for him is finished with the exception of wiring [it was originally electrified like the 1913-14 cars even though it was finished in 1912]. Martha and I participated on the Rhode Island Steam car Tour last summer and made the entire week with no problems. A few adjustments were made but other than that it ran well. Between chassis running and now with the body on and in full trim the odometer has recorded 2500 miles. The car weighs in at a bit under 4100lbs. curb weight. Vital statistics include a 130 inch wheelbase, 57 gallon water tank, and 20 gallons fuel capacity. The long wheelbase and the weight contribute to outstanding ride quality. With fuel, water, and passengers [it will fit three if they are moderately sized] all past the center point of the wheelbase, weight distribution is very close to 50/50. This makes for an ideal handling car on curvy secondary roads. Simply put, this is one fun car to drive! It is not as "lively" as "Effie", the first special car designed and built for Raymond. That car did survive and I am the proud custodian of it. It is about 650 pounds lighter and final gearing is a bit higher. The first car was geared by the factory at 60-57 or .95 to 1. This one is 55-60 or 1.1 to 1 to help compensate for the added weight. There was hardly anything about the build of this car that didn't require special engineering to achieve the very low profile. My son in law, Mark Herman, and one of his employees, Peter Kruger; deserve most of the credit for overcoming the numerous engineering problems. A special thanks to Steve Baldock and Basil Craske for designing and fabricating the special steering arms off the front axle and the arm that connects to the steering quadrant. These changes were necessary since the boiler and burner are well behind the front axle to prevent the burner from contacting the front axle on a bump. As a result the steering radius was very limited until Basil and Steve made longer ones from a special strong steel that matches the contour of the originals beautifully. While we were blessed with many exterior pictures taken when the car was in it's prime [courtesy of Ray Stanley's original photo album and the Stanley Museum] there were no pictures of the inside detail of what the factory did to lower the car almost 9 inches compared to a typical production model. When I decided to duplicate this car most Stanley people looked at the original pictures and said "Why would you want to do that car? It is ugly! The windscreen and disc covers over the wheels drew the most criticism. What I saw was the picture of Ray standing beside the car and the top of the door was the same height as the buttoned jacket at his waistline. I knew then that this car was extraordinarily low and might just be better looking in the "flesh" than the picture suggested. Although still controversial, the car draws many very favorable comments. When parked next to other Stanley's the car stands out since it is so much lower and a frequently asked question is "is it a racing model"? This car and my other steamers will undoubtedly cover many more miles this summer starting with the Eastern Steam Car Tour at Lakeville, Connecticut the second week of July. Since driving a Stanley is my favorite pleasure, I have given up trailering to events. The cars are driven over the road, used all week, and driven home unless the tour is at least over 750 miles away, then I usually ship it and fly in for the tour. My trailer is now used strictly for retrieval purposes only when there is a break down I can't overcome on the road. On July 4th 2017 Jay Leno gave the car its ultimate test. "Jay Leno drove my Stanley "Ray's Car" up the mountain successfully without any trouble. Bill Barnes followed with his Vanderbilt Cup Racer and also had no problems. As expected, we did stop once to pump water into our boilers with a wheel jacked up. The production crew doing the filming consisted of 40 people, all very skilled and experienced. They had 12 cameras attached to my car and two of the film crew sat in the rear of a minivan facing rearward, so as to capture the event. Then there was the helicopter that flew directly above us capturing it all on film from above. It was an exciting day, and everyone enjoyed it, including Jay, who was very gracious and friendly in every way. The weather was perfect with the exception of the summit, where it was cloudy, windy, and cold. Two ramp trucks took both cars down without incident, and more filming was done when they were unloaded at the bottom. "Jay drove Bill's Vanderbilt Cup Racer the day before and had to be impressed since it has a 30-H.P. engine, and his has only a 20. Bill's car is easily the fastest Stanley I have ever had the privilege to drive! Jay also rode one of Bill's steam motorcycles and must have liked it because he didn't return for over 20 minutes. Unfortunately, the film crew was not on hand to capture Jay on Bill's bike. All in all, it was an exciting day for everyone. The show, "Jay Leno's Garage," will air our climb to the clouds sometime in the fall. We will know exactly when beforehand." On the same day as Jay Leno's climb, Lisa Cantor, accompanied by her husband Mark, drove their 10-H.P. Stanley to the top, becoming the second woman to pilot a steamer to the summit. Congratulations, ALL! Rest well, Flora and F.O., after 118 years. Below are some mostly unseen photos of the restoration. |

Archives

December 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed