|

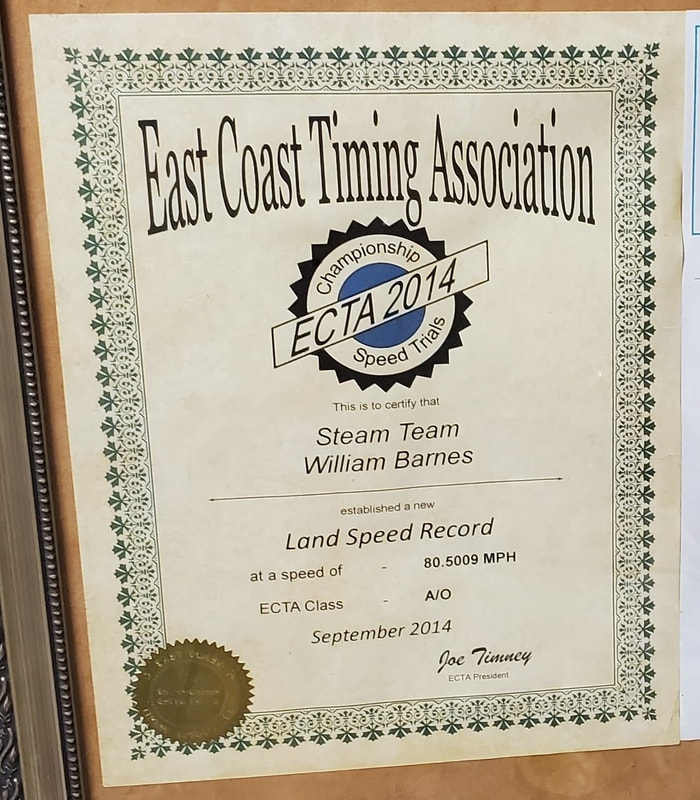

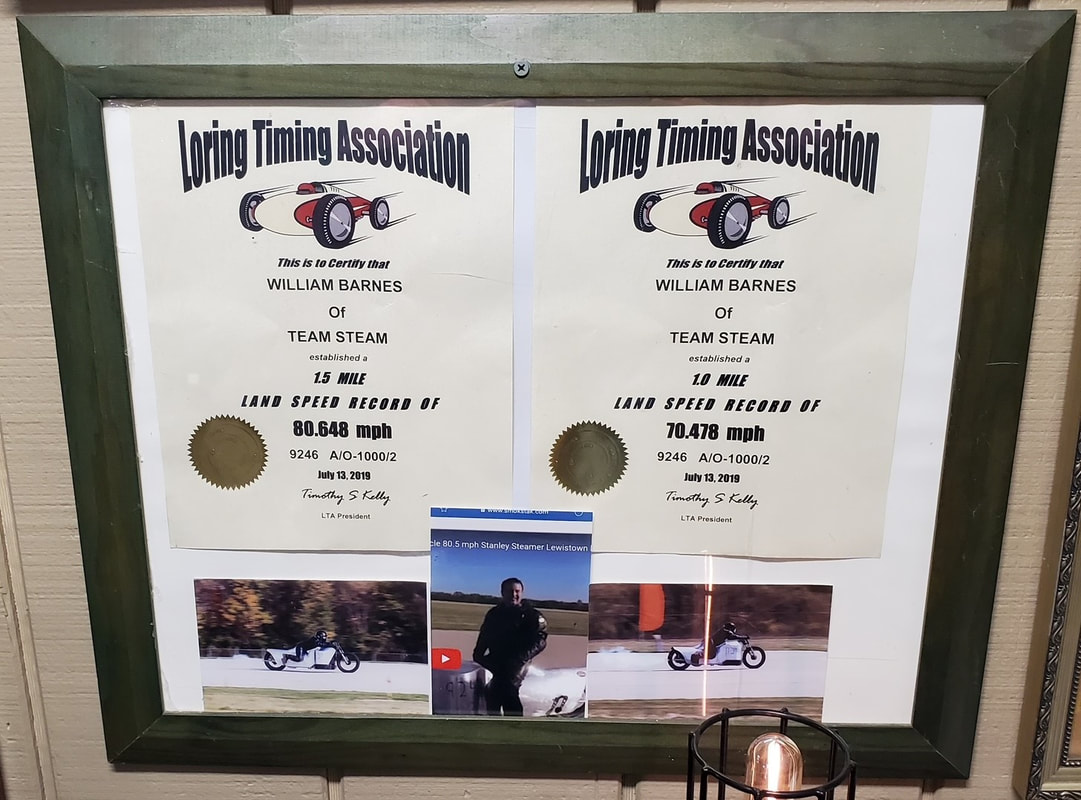

Billy Barnes Land Speed Record by Rick Heinig credit to the Steam Automobile Club of America PART ONE One of the main reasons for visiting Billy was to discuss how he ran the mile at Loring Airport and or the Ohio Mile along with what key elements lead to his success to date. The general agenda to the visit was to talk about the record attempt, the configuration, and how the “D” slide valve was set up. I was traveling to Georgia to talk with another steam Land Speed Record (LSR) seeker, Bob Sarda (another future article). I met with Billy Friday afternoon October 29th, 2021 at his shop. One common element between Billy and me is that we both have a 10 HP Stanley Engine. Actually, Billy has several engines and is in the Steam car restoration business following in his Dad’s footsteps. I’m in the process of rebuilding my 10 HP Stanley engine and was curious to any insight that Billy could offer me. I do want my Stanley car to be a real good performer. I present this article here for I think it would be of interest to SACA readers. Hope you all enjoy it. Billy’s shop is old school. Nothing like using vintage equipment to build and repair period steam automobiles. I got the nickel tour. Barnes’ shop is at 1728 Glenwood Avenue, Lewistown, PA. It is about a three hour drive south from where I live in the Elmira/Corning, NY area. There are all kinds of Stanley steam engines and cars around his shop. One was a neat looking Steam travel all type of car or should I say coach bus. I saw progress on a Stanley K, Gentleman’s Speedy Roadster (GSR), which will sure to be a stellar speedy performer. The K will receive the same size Stanley engine that goes into the Mountain Wagon. The steam engine is a twin cylinder, double acting 4-1/2 X 6-1/2 bore and stroke respectfully. This same size is what Billy says ran the LSR for the Stanley brothers in the early 1900’s. I can surmise that Billy is all about speed. From then on we started talking about land speed records. Billy holds the land speed record for a steam powered motorcycle as shown in the Loring Timing Association Certificate - picture(s) at slightly north of 80 mph over 1-1/2 miles. Also included is the East Coast Timing Association Certificate as pictured. Billy described one of his steam motorcycle speed record attempt. He starts off with relatively low pressure (200 – 400 PSI) in fear for someone getting hurt in case of a boiler rupture while building pressure before the race. He likes to run the mile at 1,000 PSI and with the engine set at cut-off, AKA hook-up and full burner all the time. He literally just gets rolling and goes into hook-up. At the start of one of his runs, he was just slowly moving along because his boiler pressure wasn’t up to where he wanted it. The race monitor called out to Billy asking if everything was alright. He was following in a chase truck. It is hard to explain the situation with steam and building up pressure. As the bike speeds up, the draw increases on the burner through the fire tubes and greatly increases the boiler pressure. He has his engine steam exhaust set up to help draw the combustion gas through the fire-tubes. It is a non-condensing system. Billy runs a custom motorcycle frame; 10 HP fire-tube type, Stanley boiler, and 10 HP Stanley engine with hook-up. The engine would be considered a dry engine (oiled before each run). His bike is pretty much a standard motorcycle frame with standard wheels and brakes. Not too many frills and enough equipment to get the job done. Gear train is from engine to a jack shaft and then to the rear wheel. The gearing is set for an engine speed of ~500 RPM to produce 100 mph. No need for feed water pumps nor check valves and just the bare essentials to run a mile at speed. He just runs with the energy stored in the 10 HP Stanley fire-tube boiler. From a personal interest of mine, I wanted to know more about the steam engine valves and was a large part of my reasoning to visit Billy. I own the same 10 HP Stanley engine that I’m using on my 84% scale version of a GSR. My engine is an earlier version where Billy’s is a later version with hook-up. Note that a 10 HP Stanley is a 3 X 4 bore and stroke respectfully. One of my keen questions on running the mile is how you set up the valves. We discussed at length the steam lap, exhaust lap and lead on the engine. Billy refers to the lead as timing. One secret to the valve setting is to set the timing in the hook-up mode. At piston top dead center, the valve needs to be slightly open allowing steam into the cylinder. It is like the early days with cars where advancing the spark. This allows steam to enter the cylinder before the piston reaches top-dead-center. Why? After some deep thought on the matter, the reason is that when running steam engines at speed in hook-up, they have something known as wire-draw from the valve. The speed in which the steam travels (mass flow rate) isn’t quick enough to fill the cylinder and get enough power through the shortened admission in cut-off. Also, the key reason for running in hook-up is to conserve the steam at pressure and allow for it to do its expansive work in the cylinder. Pressure correlates to engine speed and that’s what is needed to set speed records. Hence the reason he runs with the 1,000 PSI pressure.

After my Barnes’ visit, I spent some time looking at my 10 HP engine and doing a valve simulation. Then imagined what happens to the valve travel in hook-up. I believe that the way the eccentrics are positioned in the Stephenson’s Linkage that, when the valve mechanism is lowered, the resultant valve travel allows for the increase in lead. This confirms Billy’s statement to set the timing the way he does. He even says the engine runs smoother. Very interesting information and gets me thinking about setting up my own engine on my GSR. So I set up a valve simulation with the crank angle, eccentric angle setting, and valve lap (mainly steam lap). Each eccentric is positioned 135 Degrees from the crank position, one for forward and the other for reverse. From the pictures, the crank is measured to the keyway, and eccentric to the keyway to establish the 135 degrees. This information establishes the initial set up for a valve simulation. One of my questions to Billy was “What if we increased exhaust lap to conserve pressure”. He is willing to make a valve like this to check it out. I want to do more simulation before we go to metal. Another question I ask myself pertaining to steam engine design, do you set the angle, the Lead, and then apply Lap. I believe the angle of the eccentric sets the cutoff at least as the starting point. Also there might be a reason for this angle setting in concert with the reverse eccentric to help with the advance that Billy would set with hook-up engaged. In looking at the picture of the end view of my eccentric, at top dead center, both the valve rod followers will favor the one side at top-dead-center. So, when pulling into hook up, the valve timing (as Billy describes it) will be advanced. I wonder if all Stanley Engines are configured this way. If this were the case, then all Stanley’s will start with 50% cut-off. My research is not complete as of yet. I’ll be observing and evaluating as I rebuild my engine for my GSR. Back to Billy and his plans, he will be trying to improve upon his record with a new built engine with aluminum pistons and valve settings as described. He has a recommendation to a would-be LSR car builder to use two (2) 20 HP Stanley Engines on top of one another with the crank gears in mesh. I believe that this is actually a good idea. We’ll be keeping a look out for Billy’s next LSR attempt. And we’ll keep egging him on to run the next motorcycle, steam LSR and perhaps LSR automobile. Last thing to mention about Billy Barnes is that he is passionate about Cystic Fibrosis (CF) and Multiple Sclerosis (MS) for personal reasons. Jay Leno indorses Billy; he would ask you to give to this worthy cause(s). Thanks for reading and look for a future SACA presentation about valve timing on my 10 HP Engine. Kind regards, Rick

0 Comments

Billy Barnes Land Speed Record by Rick Heinig credit to the Steam Automobile Club of America PART TWO The East Coast Timing Association and Loring Timing Association certificates awarded to William (Billy) Barnes known as the Steam Team. Billy holds the land speed record for a steam piston powered motorcycle. The motorcycle frame that was used to set the land speed record for a steam powered motorcycle. The round portion is where the Stanley 10 HP boiler sits. This is a brand new, customer's 20 HP Stanley Engine just uncrated. It was shipped in from the UK. It is slated to go into a Gentleman's Speedy Roadster Billy is no stranger to Stanley Engines. His shop is full with new, used and pieces of Stanley Engines for incorporation into customer's cars, rebuild or components for rebuild.

|

Archives

December 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed