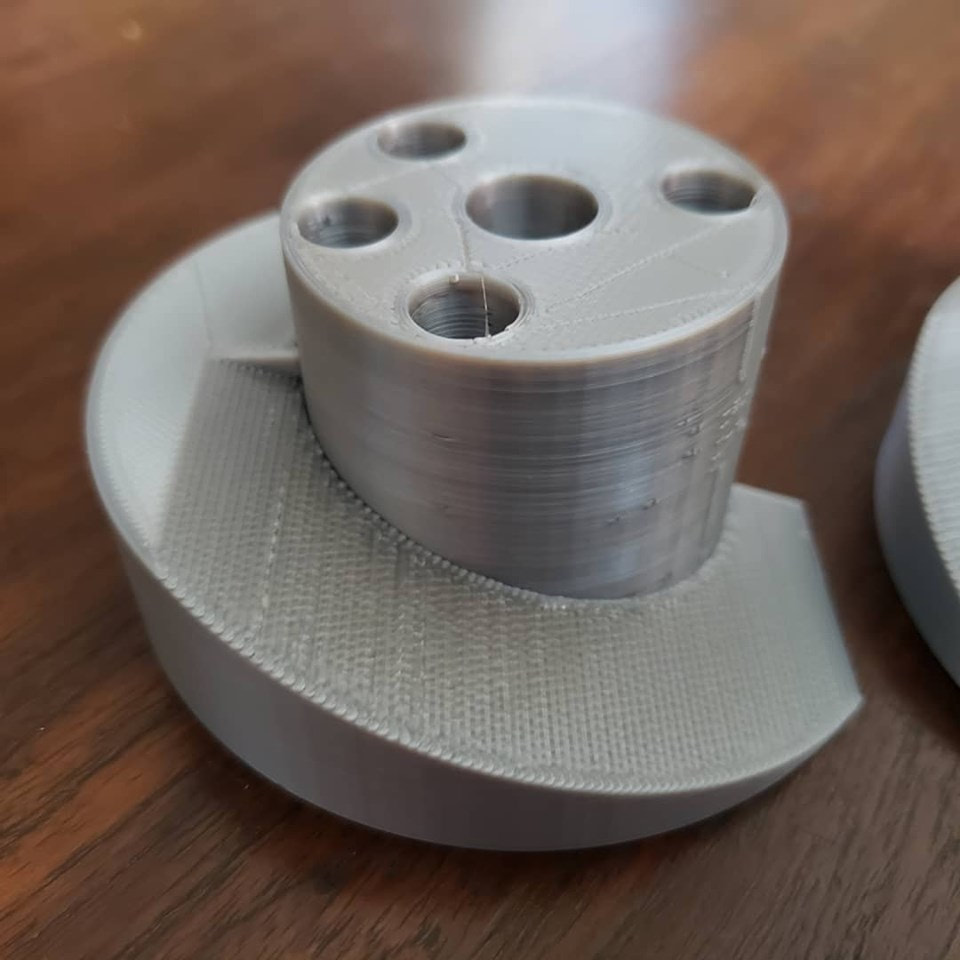

Winding steam generator coils7/30/2019 Spring City Steam Works Reports: 22nd July 2019 While it's crazy hot and in between the new kid prep.... I'm printing some fixtures to test out and help decide on the fixtures for the pancake coils for the Mason. Hopefully a little bending and fixture time this week! 23rd July 2019 One may have been thinking... Why the need to pallet jack the weld table around.... Well, I'm trying to take a 21 foot piece of pipe and wind it into a double stacked pancake flat coil of pipe to replace some coils in the Mason's monotube steam generator. Shops too small, so out in the driveway it goes!! As for the 3d printed pieces, I'm working out how to fixture the hairpin bent pipe so that the top leg is ~1/4" gap above the lower when it gets wound into a coil. The center section will be made of steel and there will be a clamp on top as well as the pipe getting tack welded to the clamp. Then the 11 foot long top pipe will swing a huge circle as the lower pipe is wound on itself to make the pancake coil. The whole mess then gets flipped over and hopefully that leg winds into a nice pancake below it. Works in my head, got to refine the pieces a little and make some chips and then try that plan out!!! 23rd July 2019 Just like the picture. A couple more steel parts to go... Then we bend! 24th July 2019 You know, I don't love going to the scrap yard for metal too often.... The first disc I had was apparently ar36 or something similar - ar for abrasion resistant armor plate I think. It had some questionable marks and when a drill hit it.... It just polished the drill. Argh. So some late night cutting on the cnc plasma with some 1/2 plate we found in the stash and this morning we have a nice fixture plate drilled up and ready! Thanks @linfield_garage for the help. 25th July 2019 Progress everyday in between all the rest of life. The platten is mounted and looks like my pins for bending and locking (the spring back) all fit up nicely. The center mandrel is fitted and I printed another test ramp to clear a lock collar. My hope is that maybe the collar will be enough lock that I don't have to tack weld the pipe. Gotta make the top clamp and the clamp to draw the pipe through yet. Hopefully a few more days at most and we'll be trying out coil bending! 26th July 2019 Well.... We are dangerously close. I need to reprint one last ramp and get a couple longer bolts. Then it should be go time. The lock collar looks good for the first coil. May have to tack weld something on the flipside for the second coil. The brass block in the back puts tension on the pipe for the bending but also pivots as the coil grows. This was the second attempt as I had a brain fart on using the hole closer to the disc but it would have interfered. Minor setback.... 27th July 2019 I just had to try it tonight after a hardware run. I must say, I would call this quite successful for the first (half) coil! Super stoked about the result. A few tweaks and changes in the process but it worked really well so far! 27th July 2019 Well lots of thought, planning, and procrastination and then in a few hours - *poof* - new coils! It's feeling nice that I can get the car back out and start fitting these in the generator. With some luck, it shouldn't take too much to connect these back up!

0 Comments

Leave a Reply. |

For instructions on how to add to our community's blog post, please visit our Get Involved page by clicking on the link above!

Archives

November 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed