|

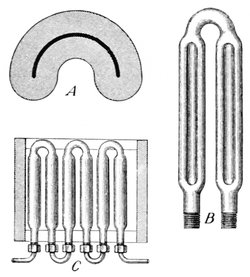

Condensed from a report to the Third International Automobile Congress, held at Milan 24th-29th, May, 1906. By Leon Serpollet (Article Courtesy of Light Steam Power, November-December 1970) When sending a copy of this report, Mr Thos. Hindle states : “It is evident that the Steam Car would not have languished….had Leon Serpollet lived. His fundamental proportionate feed system which, in it’s perfected form, embraced the positive and concurrent delivery of liquid fuel, combustion air and feed-water, has practical possibilities today (1970). Serpollet was the first to propose electric ignition for a Steam Car spray burner. It is also noteworthy that in 1905, he abandoned his famous single-acting engine for a double-acting version which, however, retained the essential poppet-valves actuated by a sliding camshaft.” (To be Continued).  Diagram of a Serpollet flash boiler. Note the thick wall of the tube, which provides a store of heat.Diagram and caption courtesy of https://en.wikipedia.org/wiki/Flash_boiler Diagram of a Serpollet flash boiler. Note the thick wall of the tube, which provides a store of heat.Diagram and caption courtesy of https://en.wikipedia.org/wiki/Flash_boiler “It is true that the Serpollet single and double-acting (D.A) engines, in the interests of simple foundry-work, had common ports for steam admission and exhaust, also that these were, in some cases, especially in the double acting version, undesirably long. These factors were of much less importance for use with highly superheated steam than they would have been using saturated or wet steam. In fact, the Darracq-Serpollet Steam Omnibus Company was still using the Serpollet D.A. engine in 1912. The first D.A engine fitted to the 1905 Serpollet Steam Cars had two horizontal side-by-side cylinders of approximately 3 inch bore and 4 inch stroke, the two cranks being spaced at 90 degrees. The larger bus engine had cylinders 3 3/4 inch bore by 4 1/2 inch stroke, and in latter models the differential gears were housed in the engine crankcase, with chain drive to each rear wheel.” “Serpollet acknowledged the advantages of the compound engine, but concluded that its use would be justified only for powers large than that regarded ample for bus-work in 1906. The text of the report of which follows appears in the “English Mechanic” of 1906, but I am under the impression that it was quoted from another source which had direct access to Serpollet’s original paper.” “The report had a modern and factual flavour, and it is difficult to realise that it was composed no less than 64 (now 109) years ago. A useful exercise would be to prepare a specification for a modern model Serpollet Steam Car!” The following has been condensed from a report by Leon Serpollet to the Third International Automobile Congress, held, from 24th-29th May, 1906, at Milan, Italy. For some years past, and particularly at the present moment, the automobile movement is developing in two parallel directions, denoted, respectively, by the touring vehicle and the commercial vehicle. We should, perhaps, keep these two classes of vehicle separate, as they respond to different requirements, and require the utilisation of different means; but in the present paper we will try to discuss them together, as they possess many points of similarity, and the economy, which is such an important factor in the commercial vehicle, is only another desirable feature in a touring car. Steam Generator The automobile steam generator should be inherently light, strong, and quick to start in operation. Have a high steaming capacity and high busting pressure. Tank boilers of automotive type are no longer employed except for portables and traction engines, on account of their great weight, the long time required to get up steam, their low busting pressure, and particularly the risk to which they expose the often mechanically ignorant people into whose hands they are placed. At the present time there are only two types of boilers in use- viz., multi-tubular boilers, with small water capacity, and flash boilers (monotube steam generators) producing superheated steam. Representatives of the former type are the Bollee, De-Dion Bouton, Trepardoux, Field, Turgan-Foy, Scott, Thornycroft, Purrey, Stanley, etc.. (The manufactures of several of these boilers have abandoned the steam system in favour of the hydrocarbon system.) The second class of boilers includes the Serpollet, Renard, Chaboche, Miesse, White, Weyher and Richmond, and others as yet little known. Nearly all the generators of the first class are comparatively heavy and cumbersome, and are heated by means of coal and coke, which renders them better adapted to commercial vehicles. Only one of the boilers, the Stanley, is heated by gasoline, but with this boiler the driver is obliged to watch the water-level. Stanley boilers are at present only applied to touring vehicles. Superheated Steam Flash Boiler Although flash boilers were the object of patents at a much earlier date, the Serpollet generator is at present a classical type. The advantages of this generator may be recapitulated as follows:- (1) Very small water capacity and forced circulation, the boiler in working order containing only an inappreciable amount of water and steam ; (2) the power may be varied within wide limits by simply varying the feed, thus instantly varying the pressure according to the demands; (3) all generators of thus type are constructed of soft steel tubes, either wound in spiral form or in the form of a grid ; these tubes of small diameter and relatively large wall thickness combine a small water capacity with a high resistance to rupture and a large heating surface ; (4) owing to the small water capacity any defects in the tubes due to wear resulting from excessive heating do not present any danger ; (5) the division into sections connected together by interior joints permits of quick removal, renewal or isolation of defective sections ; (6) this division into sections and this method of connection also permit of a rational circulation in the nest of tubes or the efficient utilisation of the heat. Through the sectional method of construction is the usual one, some generators have been constructed with the tubes in a single piece brazed together; (7) superheated steam, although requiring a somewhat special construction of the motors, presents the following advantages : High fuel economy, low feed water consumption, and consequently great facility of condensation. In order to fix ideas of the value of apparatus of this kind, we give below the principal dimensions of one of these generators applied to a Renard road train, capable of supplying steam continuously for a motor of 50 HP, which may be worked for short periods at 80 HP and more : Total height (burner and firebox included) 40 inches.; total width 19.2 inches.; total length (connecting box included) 30.8 inches.: total weight (burner and casing included) 680 lbs.; total length of tube ( all coils in series) 485 ft.; outside heating surface 97 sq. ft.; total capacity of four gallons ; rate of evaporation 12 lb. per square foot. This type of generator is built without any special attempt at lightness, an is thoroughly commercial design. The rate of evaporation varies from 5 lb. to 17 lb. per square foot per hour, according to whether one wishes a very light generator of high steaming capacity, and necessarily high fuel consumption, or an economical generator without too much restriction on the weight. Flash boilers are not subject to the disadvantages of incrustation ; there are numerous reasons why no deposit can form in such a generator. The high speed of circulation, the use of condensers which purify the water, the traces of oil carried back to the tank by the water of condensation, and the continued displacement of the point of vapourisation render them entirely proof against incrustation, except under some unusual conditions.

0 Comments

Leave a Reply. |

For instructions on how to add to our community's blog post, please visit our Get Involved page by clicking on the link above!

Archives

November 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed