|

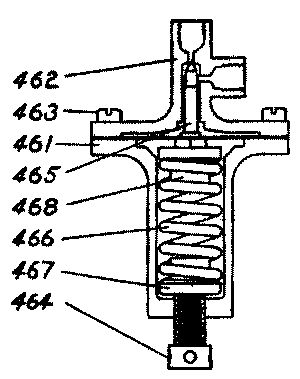

At the top of the fuel pressure automatic is a copper disk or diaphragm. This diaphragm is clamped between the two halves of the shell of the fuel pressure automatic (461 & 462). The underside of the disk rests against a washer (468) which helps to keep the heavy spring (466) centered while fuel pressure is admitted to the top side of the disk. An adjusting screw (464) and washer (467) allows for the spring tension against the disk to be set such that the diaphragm doesn't start moving and compressing the spring until the fuel pressure reaches 140 the required pressure. Mounted to the opposite side of the disk is the valve stem (465) which follows the position of the diaphragm. The valve body is an integral part of the fuel pressure automatic's shell (462) as shown in the diagram. The fuel used from the main burner pressure tanks is piped to the right port of the burner fuel automatic. A line connected to the burner (main) fuel tank is connected to the port at the top of the fuel pressure automatic. Normally the valve stem (465) is pressed tight against the valve seat (462) and no fuel passes from the right port through to the left port. When the fuel pressure exceeds the set pressure (the normal set-point of the fuel pressure automatic) the diaphragm overcomes the spring force against it and it moves slightly (down in the diagram) to compress the spring (466). As this motion happens the valve stem (465) moves off the valve seat (462) opening up the passage between the right port going to the fuel pressure tanks and the main fuel tank. This action allows fuel to flow back to the tank and for the system pressure to be maintained at the set pressure. When the fuel pressure pressure drops the spring force overcomes the fuel pressure acting on the disk and the diaphragm moves such that the valve stem (465) returns to being seated and thus fuel will not pass though the automatic. During normal operation the majority of the fuel pumped by the power fuel pump is returned through the fuel pressure automatic to the fuel supply tank. When the hand fuel pump is used the fuel pressure automatic also limits fuel pressure.

0 Comments

Leave a Reply. |

For instructions on how to add to our community's blog post, please visit our Get Involved page by clicking on the link above!

Archives

November 2022

Categories

All

|

|

|

Steam Car Network functions as a resource for all steam car and steam bike enthusiasts. The website is constantly updated with articles, events, and informative posts to keep the community alive and growing. Feel free to contact us if you have any questions or concerns at the email address below and we will promptly reply.

[email protected] |

RSS Feed

RSS Feed